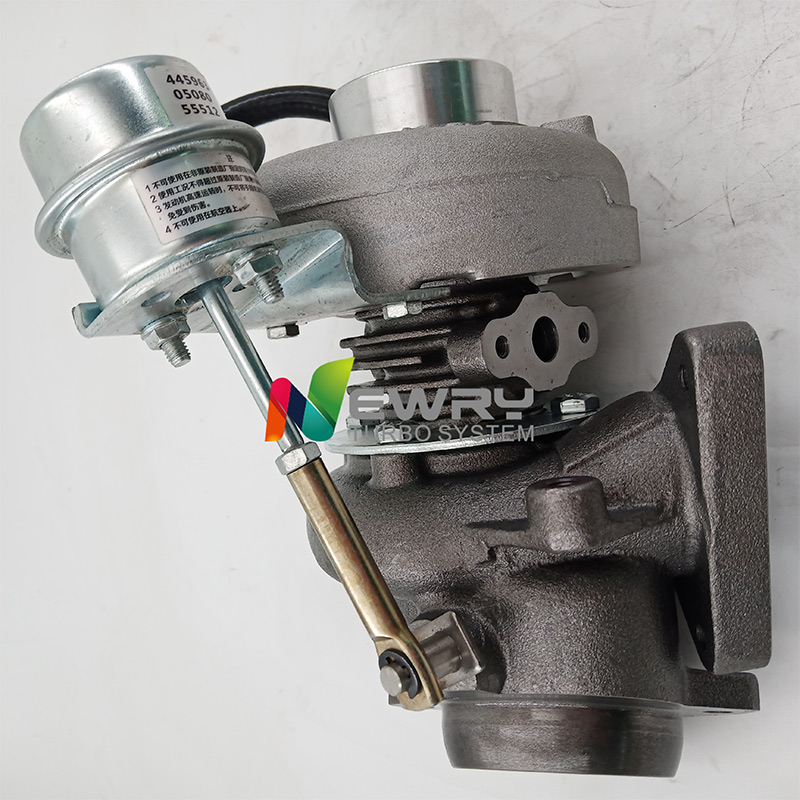

Turbocharger TB25 717123-0001 A6620903080 Ssang Yong OM662

Turbocharger TB25 717123-0001 A6620903080 Ssang Yong OM662

• Guaranteed Exact Fit For Easy Installation

• 100% BRAND NEW Replacement Turbo, Premium ISO/TS 16949 Quality - Tested To Meet Or Exceed OEM Specifications

• Engineered For High Efficiency, Superior Durability, Low Defect

• Sample Order:1-3 Days After Receipt Of Payment.

• Stock Order:3-7 Days After Receipt Of Payment.

• OEM Order:15-30 Days After Receipt Of Down Payment.

Package Included:

• 1 X Turbocharger Kit

• 1 X Balancing Test Certificate

| Part Number | 717123-5001S |

| Previous Version | 454224-0001, 717123-0001, 717123-1 |

| OE Number | A6620903080 |

| Year | 1997- |

| Description | Ssang Yong, Daewoo Musso |

| CHRA | 443854-0150 (443854-0156, 443854-5150S) |

| Turbo Model | GT25C, TB25 |

| Engine | OM662, OM662 Euro-2 Mercedes-Benz |

| Engine Manufacturer | Mercedes Benz |

| Displacement | 2.9L, 2900 ccm, 5 Cylinders |

| Power | 120 HP |

| KW | 92 |

| RPM Max | 4000 |

| Fuel | Diesel |

| Angle α (compressor housing) | 270° |

| Angle β (turbine housing) | 22° |

| Bearing Housing | 435209-0010 (1100025450) |

| Turbine Wheel | 435354-0010 (Ind. 53.1 mm, Exd. 38.5 mm, 9 Blades)(1100025437) |

| Comp. Wheel | 447449-0010 (Ind. 38.6 mm, Exd. 52.1 mm, Trm 55, 6+6 Blades) (1100025402) |

| Back plate | 432280-0001 (1100025300) |

| Heat shield Number | 443594-0001 (1100025341) |

| Repair Kit | 709143-0001 (1100025761)(dynamic seal) |

| Turbine Housing | 433077-0026 |

| Compressor Cover | 409589-0527 |

| Actuator | 433452-0026 |

| Settings Waste gate (pressure) | 0.580-0.630/0.713-0.773 bar |

| Settings Waste gate (lifting rod) | 1.0/4.0 mm |

| Gasket (turbine inlet) | 210305 (Inox Steel) |

| Gasket (oil outlet) | 210306 (Paper) |

| Alternatives | 735554-0001 |

Applications

1997-2005 Ssang Yong Musso with OM662 Engine

Related Informations

Inspecting the Turbine Wheel & Shaft Assembly

This is the most vital and costly component in the entire turbocharger. It’s critical that this part be well evaluated for a successful rebuild. Use the 1-inch micrometer and measure both portions of the turbine shaft where the bearings have been riding. Measure and write down the compressor and turbine end shaft diameters to the fourth decimal. Be sure to rotate the shaft slightly to ensure that it measures round.

Next mount the turbine shaft into a V-block as shown. Place the dial indicator on the end of the stub shaft just before the threads. While holding down tightly on the V-block, slowly rotate the wheel and watch for dial indicator reading variance. Ideally you will not see any measurable run out.